September 27, 2019

As the plastic wastes are becoming nuisances and are menacing the environments and the ecosystems, some innovative persons came up with a wonderful solution – to pave the roads with plastic wastes. This idea had been around for sometime and a few countries had actually put that into practice. Now that trend is catching up and getting more attentions from the eco-conscious nations from across the globe.

The evolution of the road constructions have come a long way. From the dirt roads to gravel roads, cobblestone roads, metaled roads, tar roads, reinforced cement concrete roads, asphalt concrete roads, etc. The modern road paving started with the use of coal tar or bitumen, which is a coal product that contains +/- 95% carbon and hydrogen, approximately 1 – 5 % sulfur, 1% each of nitrogen and oxygen, plus a small trace of minerals made up the rest. Later the use of tar was reduced when the asphalt concrete was introduced. The tarred road constructions were not environmentally friendly as they produce much noxious and pungent gases in their preparation to pave roads.

These gases contribute to the greenhouse gases that cause the global warming. To pave a road the tar had to be melted down first. A process that involved the tar barrels to be heated over the burning fire woods. In the old days whenever a new road was built or renovated or minor repairs were being carried out, we had to endure the unbearable burning smells of the tar in our residential areas. In those days we were only concerned about their effects on the health, but never took into considerations their adverse impacts on the environments or the climate change.

When asphalt concrete, which is a mixture of solid bitumen and construction aggregates, such as: different grades of small rock or shingle, cement and coarse sand prepared at a mixing plant, are introduced in the road constructions, they are far less polluting. That reduced the effects of the bitumen significantly and the residents in the vicinity of the road constructions are some what spared from the dangers of the toxic gases. The asphalt concrete roads are more durable and smoother than the tarred roads. Thus asphalt concrete roads are more environmentally friendly and are of better quality than the tarred roads.

Today, thanks to the innovators, the paving of roads using the plastic wastes are becoming more popular. This trend will definitely contribute towards the control of plastic pollution that is plaguing the world and affecting our ecosystems and are impacting on our environments. Humans and every living thing are suffering from the menaces of the plastic pollution and this innovation came as a great blessing for all of us.

Different methods of plastic road constructions

That being mentioned, let us have a glimpse of how the plastic wastes are turned into road paving materials. Plastic roads are either built entirely of plastic or are composites of plastic mixed into asphalt concrete. The plastic composite asphalt concrete road is different from the standard roads in the respect that the latter is constructed with cement concrete or asphalt concrete. Before the invention of the entirely plastic roads, the plastic composite roads, which incorporate plastic waste into the asphalt concrete mix have existed in Australia, Indonesia, India, the United Kingdom, the United States and some other countries. They demonstrate characteristics superior to regular asphalt concrete roads; specifically, they show better wear resistance. The implementation of plastics in road constructions also opens a new option for recycling the used consumer plastics.

The idea of a road made entirely with plastic was first hatched in Netherlands. Road engineers in Netherland came up with that idea. After thorough experimenting some towns in that country become the first ones in the world, where some roads are constructed with recycled single-use plastic wastes. Netherland is a country where the bicycles are mostly used by all walks of life; from the Prime Minister down to the lowest levels commute around the city by bicycles. So they first built a bicycle path entirely made of recycled plastic wastes as an experiment. When that proved to be viable they are now planning to build highways with the same technology.

The innovative and unique concept of building roads made of plastic only, would definitely contribute to solving the overwhelming problem of plastic pollution. The idea of plastic roads was conceived by looking at the problems that municipalities, provinces, regional water authorities and contractors had to deal with on a daily basis. They include societal problems such as plastic waste, extreme rain and snow, consolidation of the subsoil, an increasing need for mobility, as well as the increasingly stringent requirements for future roads.

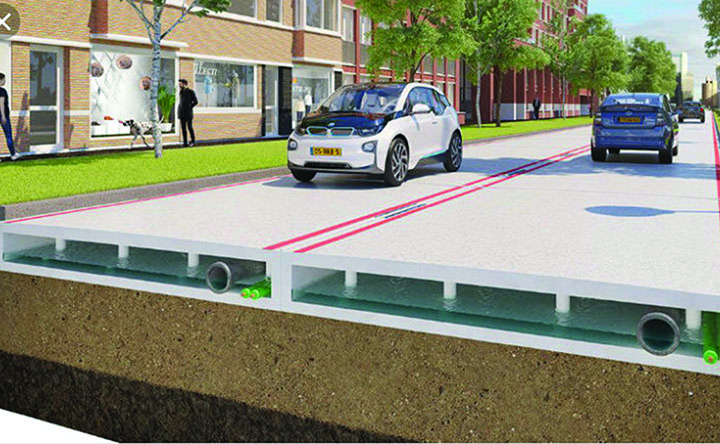

Unlike other methods of road construction, plastic only roads are constructed by using the prefabricated pallet-like plastic sections that can be assembled like the pieces in a game of LEGO. The plastic pallets have hollowed spaces that can be utilized for storing water; to accommodate electrical and telephone cables, and pipes; thus they serve multipurpose.

Advantages of plastic roads

The advantages of the plastic roads built entirely with recycled consumer single-use plastic wastes are:-

• It is a lightweight prefabricated construction that can be built pretty much the LEGO way, it is four times lighter than a traditional road structure.

• Faster construction (months shorter) and less maintenance time.

• Higher quality and a longer lifespan. It is homogeneous and prefabricated; the lifespan is two to three times longer than a traditional road paving.

• Little to no maintenance required. The material is virtually impervious to conditions such as the weather and weeds.

• The innovation is considerably more sustainable. The goal is to make the plastic road out of 100 percent recycled plastic and to make it fully reusable.

• Double use of space. The hollow space in the design can be used to store water or as space for cables and pipes.

• The possibility of constant traffic safety and water drainage.

• Everything on and around the road can be prefabricated including road markings and guardrails.

• It is scalable. The concept offers opportunities for further innovation. Examples include solar heated roads, light poles, and traffic loop sensors.

• A great added advantage is the contribution to the global social problem of plastic waste in an innovative and sustainable way.

Furthermore, the advantages these plastic roads have over their asphalt counterparts are numerous. The recycled plastic replaces a large portion of the bitumen in asphalt, which has vert high carbon concentrations. This fact alone made the plastic roads more desirable. Water, the main cause of potholes, does not penetrate it as easily as with traditional asphalt mixes and it is also more heat resistant. They do not release plastic particles into the environment – unlike some so-called eco-roads that end up doing more harm than good.

Conclusion

Consumer plastic wastes represent a serious problem that is damaging the environment and many species on Earth. Globally, more than 40 species of fish are known to consume plastic; eventually, that plastic reaches the humans’ dinner plates. Around 420 million tons of plastic is produced each year, and most of this plastic ends up polluting ecosystems around the world. As the toll of plastic pollution on wildlife becomes more apparent, countries, companies, and individuals are working to curb that problem. Thus utilizing those consumer plastic wastes in road constructions is one of the viable solutions.

Currently a town in Eastern Cape, South Africa is only weeks away from completion of a construction project – the first entirely plastic road for that country. We should also start considering to adopt that road construction technique in our country too. As a starter Mandalay would be the right choice, because plastic roads are smarter and smart cities around the world are starting to build their roads with recycled plastic. For that reason Mandalay has great potentials for the introduction of plastic roads. So, why shouldn’t Mandalay be the pioneer in plastic roads in Myanmar?

Reference:-

– Smart Cities: From Plastic Pollution to Plastic Roads – interestingengineering.com

(GNLM)